Our Work

How We Cast

Sand Casting

Sand casting is a metal casting process that involves the use of natural sand as well as small amounts of clay and is generally used for low volume products that have high complexity or are a one-off product.

Many of our sculptures use the sand casting method, but it also has applications across the automobile and industrial sector.

Die Casting

Alliance Connect supports a number of types of die casting methods, allowing us to meet a range of very specific requirements for our customers.

Die casting is especially suited to applications that require dimensional consistency, a greater level of detail and a larger quantity of small to medium surface parts with a better surface finish.

Gravity Die Casting

Suitable for low to medium volume and complexity, gravity die casting is accomplished by gently pouring molten metal into reusable metal dies under the force of gravity.

Low Pressure Die Casting

Low pressure die casting is similar to gravity die casting but uses more pressure to push the metal into the die.

Suitable for medium to high volume and complexity.

High Pressure Die Casting

In the high pressure die casting process, the metal is forced into a high grade steel tool (die) at a high speed and pressure. High pressure is used for high volume and complexity.

Suitable for components requiring precision, such as light and thin walled components.

How We Finish

Heat Treatment

Heat treatment is the process of heating and cooling metals to change their microstructure and to bring out the physical and mechanical characteristics that make metals more desirable or durable.

The most common reason metals undergo heat treatment is to improve their strength, hardness, toughness, ductility (stretchiness) and corrosion resistance.

Impregnation

When parts are created by casting metal, tiny defects are nearly impossible to avoid. Left untreated, these defects can impact performance under normal operation.

Alliance Connect uses vacuum impregnation to introduce a sealing resin that seals the surface, reduces moisture and internal corrosion and improves the quality and integrity of the part.

Shotblasting

Shotblasting is a finishing process that occurs post production to remove burrs (raised imperfections) and achieve a uniform finish. The process forcibly propels a stream of abrasive material against a surface under high pressure. Different materials can be used depending on the finish required.

Blasting is not only used for removing burrs, it can also be used to change the texture of a surface to increase adhesion or mechanical function or to provide a high-quality cosmetic finish.

CNC Machining

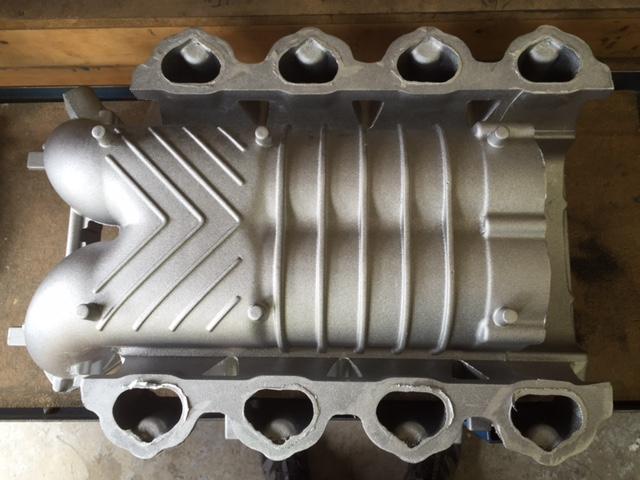

Sometimes cast parts can be used as they are when they leave the mould.

Often, they need to be machined to provide a smoother surface or threaded holes or to remove the bits of metal not required.

Alliance Connect machines all its own castings, which means there is an in-depth understanding of the properties of each die.

Other Services

Anodising

Anodising is a process by which the natural film on aluminium is greatly increased in thickness and strength.

Aluminium is naturally quite soft and has a thin film, which means it is easily damaged.

Increasing the film's thickness makes it more corrosion and abrasion resistant and allows it to be used for insulation.

Plating

Plating is a method involving a chemical bath that alters or coats the surface with a thin layer of metal, such as nickel or PTFE.

Metal plating can improve a product’s durability, corrosion resistance, surface friction and exterior appearance.

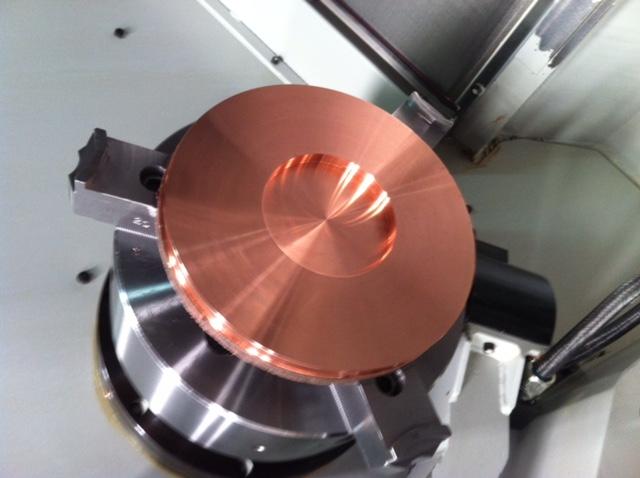

Polishing

Polishing is a process that removes the roughness on the surface and polishes the product to create a smoother, brighter finish.

There are various techniques depending on the level of smoothness, polish or brightness required.

Laser Cutting/Water Jetting

Laser cutting and water jetting are both metal cutting methods. Water jetting uses a high pressure stream of water to cut through metal, whereas laser cutting uses a laser light to achieve a similar result.

Laser is more precise, but is limited by the thickness of the metal.

Water jetting can cut any material and is able to cut through great thickness.

Powder Coating

Powder coating is a finishing process where a powder colour or coating is applied to a product using a magnetically charged spray gun.

The coated part is then placed in an oven where the powder melts into an even, solid coat across the entire surface.

Powder coating provides a durable, long-lasting and attractive finish.